Our Products

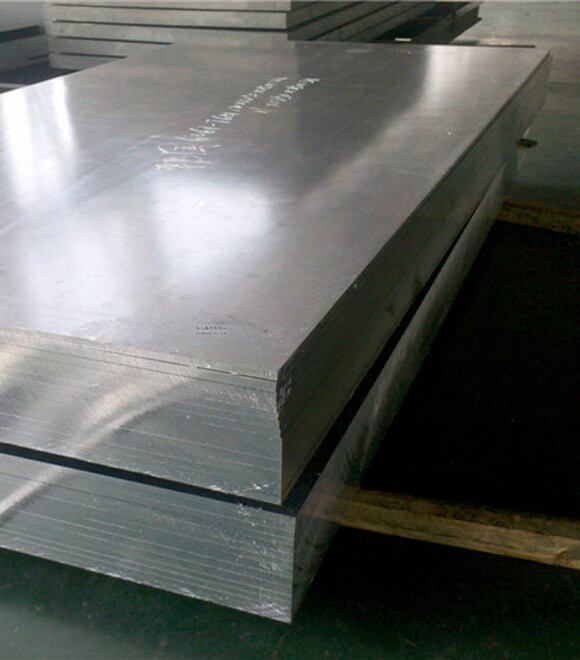

Hastelloy X Sheets Plates

UNS N06002 Plate, DIN 2.4665 Sheets

Mangalam Metal is manufacturer and stockist of Hastelloy Alloy X Sheets and Plates, which is an improved alloy for use in a range of aggressive industrial environments. Hastelloy X Plates is a nickel-chromium-molybdenum alloy, which has high resistance corrosion and metallurgical stability. Some of the area of present or potential use for Hastelloy X Coils is, Acetic acid/Acetic Anhydride, cellophane manufacturing, chlorine spargers, chlorination systems, circuit board etching equipment, etc. Gas-tungsten-arc welding (GTAW) and shielded-metal-arc welding (SMAW) are commonly used to weld Alloy X Plates, as it is produced with the Chromium content and has a higher level of Molybdenum. Alloy X Coils also resists formation of grain boundary precipitates in the weld heat affected zone making it useful for most chemical processes in the as-welded condition.

Hastelloy X Perforated Sheets has not exhibited pitting, even at the maximum test temperature (150 Degree C), because the Critical Crevice Temperature of the alloy is 75 Degree C. UNS N06002 Plate has exceptional resistance to a wide variety of chemical process environments including strong oxidizers such as ferric acids, acetic anhydride, and seawater and brine solutions. DIN 2.4665 Sheets has higher chromium and lower molybdenum content that makes the alloy more corrosion resistant in highly oxidizing media. Hastelloy X Slatting Sheets is a versatile austenitic nickel- tungsten-chromium-molybdenum alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking.

Specification Of Hastelloy X Sheets & Plates

| Specifications | ASTM B435 / ASME SB435 |

|---|---|

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm |

| Thickness | 0.1mm to 12 mm Thk |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR). |

| Form | Coils, Foils, Rolls, Plain Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Hastelloy X | 2.4665 | N06002 |

Chemical Composition

| Grade | Ni | Mo | Cr | Fe | Mn | C | Co | Si | P | S |

| Hastelloy X | Balance | 8.00 – 10.00 | 20.50 – 23.00 | 17.00 – 20.00 | 1.00 max | 0.05 – 0.15 | 0.50 – 2.50 | 1.00 max | 0.04 max | 0.03 max |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.22 g/cm³ | 1355°C | 655 MPa | 240 MPa | 35% |